Cut optimize by Excel. Algorithm for Efficiently Cutting Rectangular Members from Planks.

As it turns out, Excel is not suitable forplatecutting calculations. Because of the combinatorial optimizationproblem,a dedicated application is required.

There are macros available, so it is not theoretically impossible.However,dedicated software should be developed for the calculation volume. It isnotpossible to calculate the plate count using only functions.

How many pieces of the same size can be taken from one original plate?

However, this can be calculated with Excel.

For bars and long pieces (1dimensional)

To simplify the story, let's first consider a 1D member of the same size.

Example.

Assuming the width of the saw is 3mm, how many 200mm can be takenfrom1800mm?

Int((1800 + 3) / (200 + 3)) = 8

"Int" is here assumed to be a function that truncates after the decimalpoint,such as in Excel.

For plate (2-dimensional)

If this is 2-dimensional and all the members are the same

Example.

How many 400*300 pieces can be obtained from an 1800*900mm originalplate?

If the member is oriented horizontally.

Int((1800 + 3) / (400 + 3)) * Int((900 + 3) / (300 + 3))

= 8

If we change the orientation of the member (swap the horizontal andvertical),we get

Int((1800 + 3) / (300 + 3)) * Int((900 + 3) /(400+ 3))

=

10

In this case, the yield is higher when the part is oriented vertically.

The actual Excel sheet can be downloaded from

https://file.tubakurosoft.com/PanelCut.xlsx

Sheet image:

| X | Y | |

| Stock panel | 1800 | 900 |

| Parts panel | 400 | 300 |

| Saw kerf size | 3 | |

| Number of parts panels 1 | 8 | |

| Number of parts panels 2 | 10 | |

Algorithm for calculating a highly efficient cutting layout forcuttingplanks with shearing/panel saws, etc.

Let's consider an algorithm for calculating the cutting of severaldifferentsized members from several different types of stock panel.

First, we decide which members are to be cut.

- If there are n pieces, there are n! different orders in which to take thepieces.

- Decide from which original or leftover material the member is to be taken.The pattern is multiplied by the number of plates and remnants.

- When taking a piece of material, the shape of the end piece will changedepending on whether it is cut longitudinally or shortitudinally first. See thefigure below.

- If the member can be rotated or oriented, the pattern will be multipliedfurther.

First Fit Method - Which part is to be cut from which stock plate (or existing edge material)?

This is one of the keywords that came up in various searches to create a plate cutting software. I tried my best to read up on the method, and was disappointed to find that it was just a matter of cutting from a large part panel, even though it included formulas and a great deal of explanation. I don't remember where I read it.

Another method I found was the Monte Carlo method, but again, it was just a method where if you shoot a lot, you will eventually hit. I also found a "genetic algorithm," which sounds cool, but it's based on a better pattern, and you have to hit a lot more of them.

In the end, there is no "right" way to do it. In the end, there is no "one-size-fits-all" method, and it is usually a matter of cutting a large piece from as small a stock plate as possible. This eliminates major mistakes.

Determine the combination of components that fit together efficiently.

On the basis of First Fit, for example, for the size of a fixed length board

1800 = 900+900

1800 = 600+1200

1800 = 450*4

Assign which of the parts and which of the parts will fit well together. In some cases, it may be more efficient to assign the parts to larger stock plates and remnants. And, especially when cutting the first large plate, it is important to consider whether to cut longitudinally or shortitudinally, as this will change the efficiency later on.

What is a combinatorial optimization problem?

The only way to find the optimal solution is to enumerate and compare all the patterns. However, as mentioned above, this is impossible even with a PC if the number of members is as many as 10. The number of combination patterns increases factorially with each additional member, and the calculation time required easily exceeds the history of the universe. Therefore, it is practically impossible to find the optimal solution, and it is a very difficult problem even using a computer. This is the combinatorial optimization problem. Therefore, even if a mathematically optimal solution cannot be guaranteed, an algorithm that produces a practical result in a practical amount of time is sought.

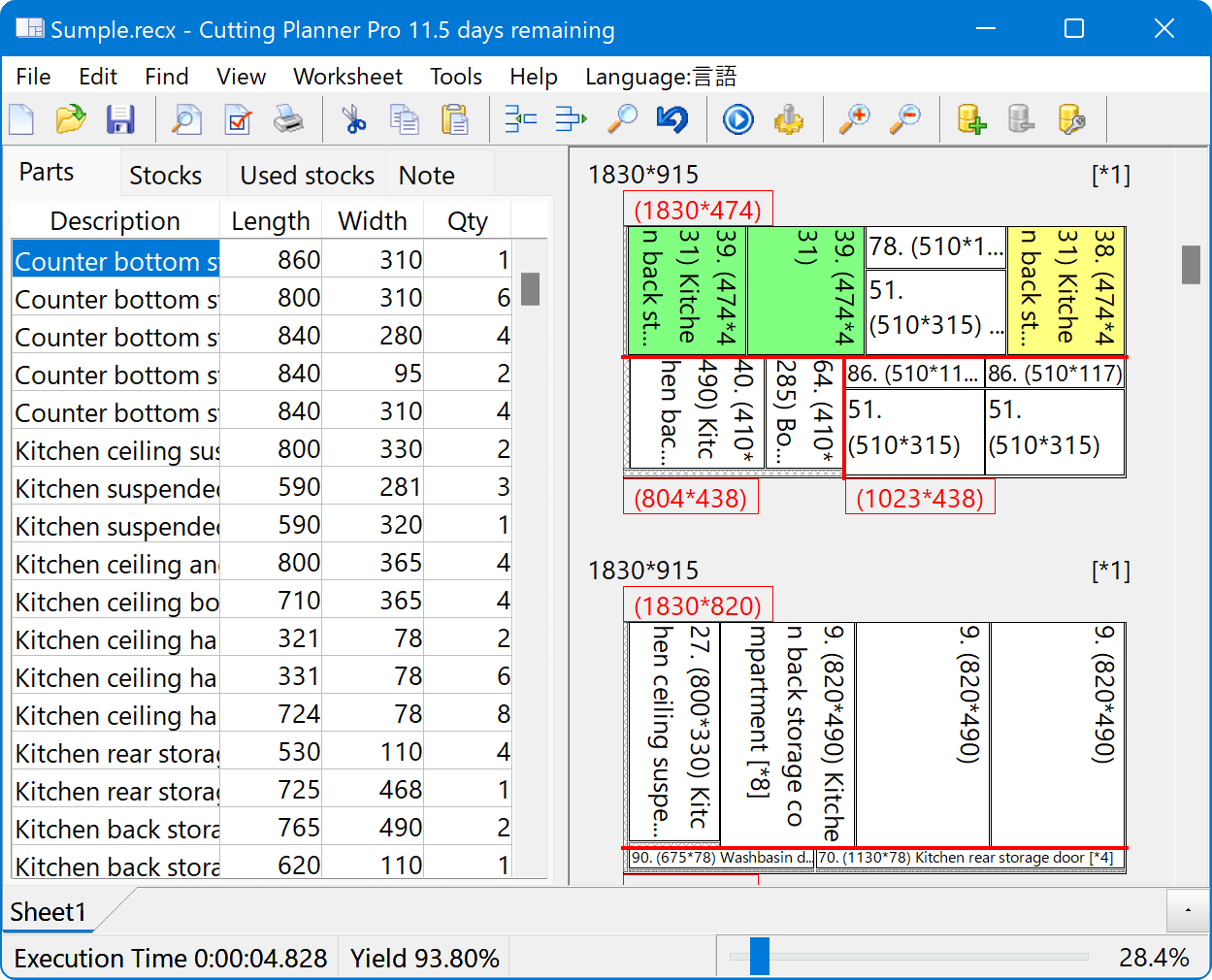

Let's use Cut optimizer.

A PC can generate a large number of patterns and select the most efficient one. However, there are practically an infinite number of cutting patterns. It is impossible to find all of them, but even if the number is infinite, most of them are "sensuously different". How to remove that is an important quality of Cut optimizer software.

With Cutting Planner, a task that would take a seasoned person hours of manual labor can be done in a matter of seconds, with practical results.

Creating a cutting plan requires skilled experience, intuition, and a significant amount of time. It is not an easy task. We have developed an algorithm that combines the advantages of computers with the experience gained from actual factory work to produce practical results in a practical amount of time.

Liner and Panel Cut list optimizer

Measures to prevent material price hikes

Free for 30 days

- Steel, bars, pipes, and other long materials:1D

- Plywood, veneer, steel plate, acrylic plate, etc :2D

Both types of material can be calculated. Saves material and labor costs.

Compatible with Windows11 (not available for trial in virtual environment)

Cutting Planner is already being used in a variety of settings, from small workshops to well-known companies.

This is a paid software, but you can use it for 30 days from the first installation with free, unlimited functionality.