.recx file format

A .recx file is Cutting Planner\'s proprietary file format, which is a .xml worksheet file that has been zipped and given a .recx extension. One .xml file is equivalent to one worksheet, so you do not need to be aware of the fact that it is a .zip file. You do not need to be aware of the fact that the file is a zip file, nor do you need to install separate compression and decompression software.

Generally, only the creator of a binary file understands the specifications of the binary format. Therefore, it may be difficult to reuse the data due to changes in the times. This software is a minor proprietary standard, and I think that leaving a large amount of data in this format will inevitably leave some concerns.

Therefore, we have changed to xml format. xml is flexible enough to accommodate future specification changes and extensions. By publishing the specifications, third parties can develop software to use the output tree plans in other applications. The advantages are as follows.

If you put extra files in the .recx, it may not work properly.

Multiple .xmls can be combined into a zip to support multiple sheets. The tab order is the order of the file list inside the zip. This allows you to create a multiple-sheet .recx file even on the command line by using the zip file creation tool.

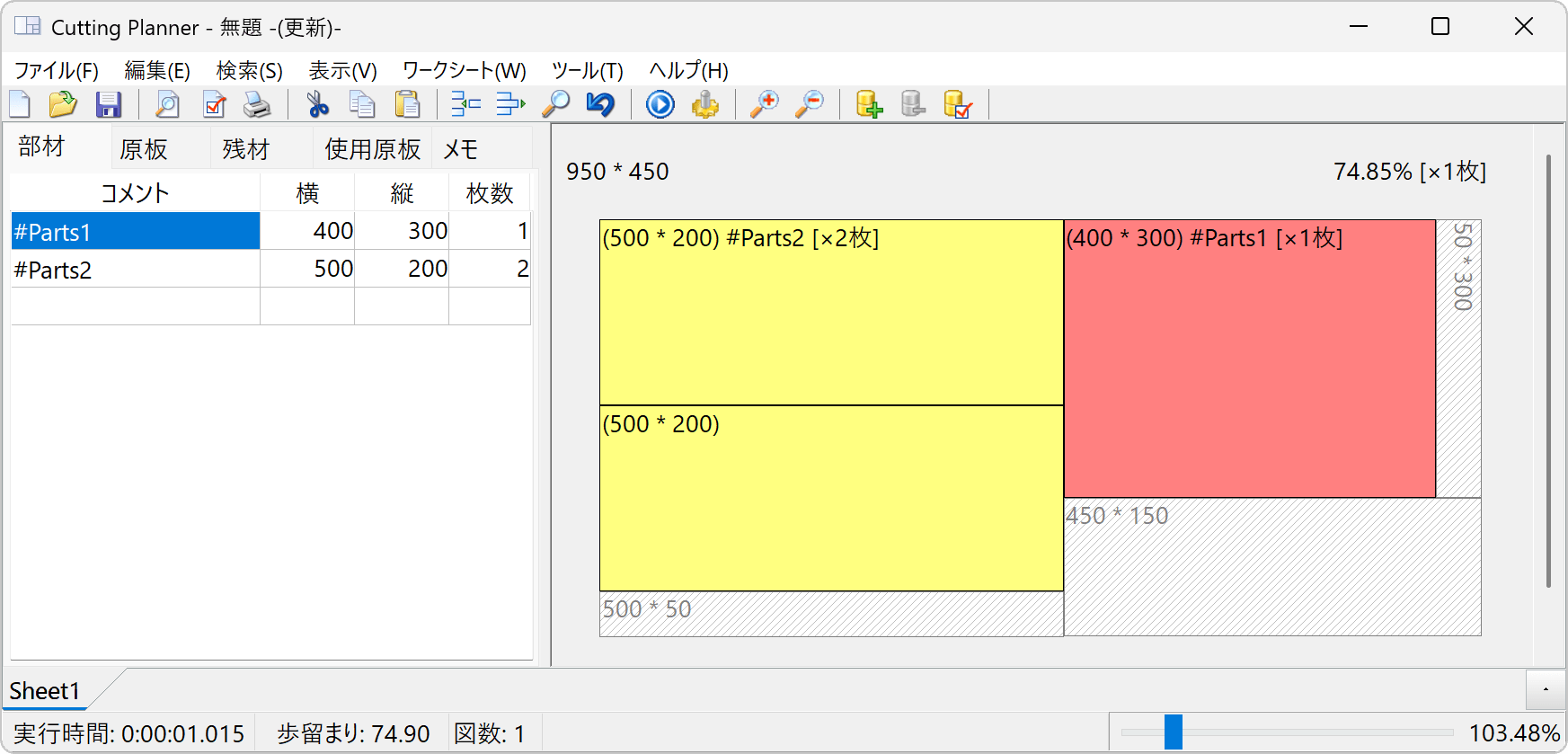

As an example, here is an xml of the following data.

Data structure

If you are only entering data,

and alone will work.

─RectPacker

├─Memo [Description]

│ └─Line [Line-by-line text]

├─Option [Option]

├─PanelSawList [1D or 2D layout pictures]

│ └─PanelSaw [layout picture]

│ └─LineData [1D] or BoardNode [2D]

├─ProcessNumberPriorityPanelSawList or RemnantsLengthPriorityPanelSawList [1D only]

│ └─PanelSaw

│ └─LineData [1D only]

├─PartsBoardList

├─PartsColorList

├─SourceBoardList [Stocks list]

├─StockBoardList [First usage stocks list]

├─SourceBoardData [Aggregated data from stocks panel]

├─PartsBoardData [Aggregated data from parts panel]

└─PrintSetUp

About parts panel and stocks panel numbers

Parts panels and stocks panels are sorted by area, and numbered starting from 0 in the order of size. If the area is the same, the longer side is numbered first, and if the area is the same, the rotatable side is numbered first.

About the Data Structure of 2D Diagrams

Cutting a board once results in two pieces. Cutting one of them will result in two pieces. In other words, the data structure is a two-branch tree structure.

The data structure can be expressed as it is by simply defining a "board" in xml. If you draw only the parts panels and unused space at the end of the tree structure, it will be as shown in the application.

If you have to read inconsistent values, Cutting Planner may not work properly. Only use the output values.

Regarding numerical values such as board size and coordinates for aggregated data

Due to the specification of the internal algorithm, the values must be integers. Therefore, they are converted to a number with the smallest unit being 1 and recorded. The value will be an integer with [Options]-[cutting optimization calculation]-[precision] as the unit of 1. For example, if the length format is a decimal point and the precision (minimum unit) is 0.1, 12.3 is 123. For fractional inches with a minimum unit of 1/8 inch, 12 inches would be 96 multiplied by 8.

Example of 2D code

The difference from 1D is explained in the comments section.

<?xml version="1.0" encoding="UTF-8"?>

<RectPacker FileTypeVersion="2.7" ExeFileVersion="13.0">

<FormatSettings DecimalSeparator="." ThousandSeparator=","/>

<Option Material="Sheet1_#1" Thickness="" SameSizePartsMerge="false" TabColor="" Problem="2D" LengthFormat="ftDecimal" Precision="1" Decimals="0" Rotate="0" SmallSourcePriorityPoint="5" PartsColorListType="1" KerfSize="3" MaxCutLength="" ConvergenceJudgmentTime="15" TopTrimSize="0" BottomTrimSize="0" LeftTrimSize="0" RightTrimSize="0" RotationalProcessesPriority="0" PriorityContinuousPartsLayout="0" DescriptionCount="1"/

<!--

<FormatSettings DecimalSeparator="." ThousandSeparator=","/>

Decimal and Thousand Separator, which are the settings for the region of the PC where this file was saved. If the file is opened on a PC with different settings, it will be converted.

Options

Material="Sheet1"

Sheet name: Material

Thickness=""

Sheet name: Thickness

SameSizePartsMerge="true"

Integrate parts panels of the same size

TabColor=""

Problem="2D"

LengthFormat="ftDecimal"

ftDecimal

ftFeetDecimalInches

ftFactionalInches

ftFeetFractionalInches

Precision="1"

Accuracy / Minimum Unit

LengthFormat = "ftDecimal"

1, 0.1, 0.01

LengthFormat = "ftFeetDecimalInches"

0.1, 0.01, 0.001

"ftFactionalInches" or "ftFeetFractionalInches"

1/8", 1/16", 1/32", 1/64", 1/128"

Decimals="0"

Number of decimal places: for compatibility with previous versions, Precision is preferred

Rotate="0"

All parts panels can rotate=0 All parts panels cannot rotate=1 Individual setting=2

SmallSourcePriorityPoint="5"

Small stocks usage rate.

SearchLevel="4"

HighRatio="1" Compatible with previous version 0 with SearchLevel=1 , 1 with SearchLevel>1

Integrated functionality into ConvergenceJudgmentTime= in Ver13.

PartsColorListType="1"

Parts panel coloring

None=0

Similar shape=1

Large size=2

Smaller size=3

KerfSize="3"

Saw cloth width

MaxCutLength=""

Maximum length the machine can cut :2D only

MinimumSearchTime="2"

Integrated functionality into ConvergenceJudgmentTime= in Ver13.

ConvergenceJudgmentTime="15"

Same as "Search Level" in the link.

TopTrimSize="0"

BottomTrimSize="0"

LeftTrimSize="0"

RightTrimSize="0"

RotationalProcessesPriority="1"

2D only

PlacementPriority1D="lrProcesses"

1D only

"lrProcesses": Priority is given to the number of processes

"lrRemnants": Remnants length priority

-->

<SourceBoardList>

<Board Comment="" Width="1000" Height="700" Count="" Cost=""/>

<Board Comment="" Width="" Height="" Count="" Cost=""/>

</SourceBoardList>

<!--

Stock panel list

In the case of 1D, the Height portion will be eliminated. Invalid values are ignored when performing cutting optimization calculations.

Comment

Width

Height

Count

Cost

-->

<StockBoardList>

<Board Comment="" Width="" Height="" Count="" Cost=""/>

</StockBoardList>

<!--

First usage stock panel list

In the case of 1D, the Height portion will be eliminated. Invalid values are ignored when performing cutting optimization calculations.

Comment

Width

Height

Count

Cost

-->

<PartsBoardList>

<Board Comment="#Parts1" Width="400" Height="300" Count="1"/>

<Board Comment="#Parts2" Width="500" Height="200" Count="2"/>

<Board Comment="" Width="" Height="" Count=""/>

</PartsBoardList>

<!--

Parts panel list

In the case of 1D, the Height portion will be eliminated. Invalid values are ignored when performing cutting optimization calculations.

Comment

Width

Height

Count

CanRotate=Rotation available =

1, Rotation not available = 0

Ignored when not set individually.

-->

<SourceBoardData>

<Board Index="0" Count="-1" Cost="0" UsedNumber="1" Priority="0" Comment="" Width="1000" Height="700"/>

</SourceBoardData>

<PartsBoardData>

<Board Index="0" Width="400" Count="1" Cost="0" Comment="#Parts1" Height="300" CanRotate="true" CanNotBeArrangedNumber="0"/>

<Board Index="1" Width="500" Count="2" Cost="0" Comment="#Parts2" Height="200" CanRotate="true" CanNotBeArrangedNumber="0"/>

<!--

Aggregated data from stock panel

Remove duplicates and invalid values and sort by area or number

Index

Comment

Width

Height

Count=-1 is unlimited

Cost

UsedNumber

Priority=First usage stocks is 1

-->

</PartsBoardData>

<!--

Aggregated data from parts panel

Remove duplicates and invalid values and sort by area or number

Index

Comment

Width

Height

Count

CanRotate=1, Rotation not available = 0 Ignored when not set individually.

Cost

CanNotBeArrangedNumber=Number of parts panels that could not be placed

-->

<Memo>

<Line>#SumpleLine1</Line>

<Line>#SumpleLine2</Line>

</Memo>

<!--

Description.

Row-by-row recording

-->

<PartsColorList>

<PartsColor Back="clWindow" BrushColor="clAppWorkSpace" FontColor="clGrayText" PenColor="clGrayText" Style="bsDiagCross"/>

<PartsColor Back="clWindow" BrushColor="clWindow" FontColor="clWindowText" PenColor="clWindowText" Style="bsClear"/>

<PartsColor Back="clGradientInactiveCaption" BrushColor="clWindow" FontColor="clWindowText" PenColor="clWindowText" Style="bsClear"/>

<PartsColor Back="$008080FF" BrushColor="clWhite" FontColor="clBlack" PenColor="clBlack" Style="bsClear"/>

<PartsColor Back="$0080FFFF" BrushColor="clWhite" FontColor="clBlack" PenColor="clBlack" Style="bsClear"/>

<PartsColor Back="$0080FF80" BrushColor="clWhite" FontColor="clBlack" PenColor="clBlack" Style="bsClear"/>

<PartsColor Back="$00FFFF80" BrushColor="clWhite" FontColor="clBlack" PenColor="clBlack" Style="bsClear"/>

<PartsColor Back="$00FF8000" BrushColor="clWhite" FontColor="clWhite" PenColor="clBlack" Style="bsClear"/>

<PartsColor Back="$00C080FF" BrushColor="clWhite" FontColor="clBlack" PenColor="clBlack" Style="bsClear"/>

<PartsColor Back="$00404080" BrushColor="clWhite" FontColor="clWhite" PenColor="clBlack" Style="bsClear"/>

<PartsColor Back="$004080FF" BrushColor="clWhite" FontColor="clBlack" PenColor="clBlack" Style="bsClear"/>

<PartsColor Back="clTeal" BrushColor="clWhite" FontColor="clWhite" PenColor="clBlack" Style="bsClear"/>

<PartsColor Back="$00804000" BrushColor="clWhite" FontColor="clWhite" PenColor="clBlack" Style="bsClear"/>

<PartsColor Back="$00FF8080" BrushColor="clWhite" FontColor="clBlack" PenColor="clBlack" Style="bsClear"/>

</PartsColorList>

<!--

Parts panel color setting list

Back=Background color BrushColor=Pattern color FontColor=Font color PenColor=Border color Style=Pattern

(For values, search "delphi VCL colors" or "Vcl.Graphics.TBrushStyle")

-->

<PanelSawList ExecutionTime="0" RotationsNumber="2">

<!--

<PanelSawList>layout-picture list

ExecutionTime=Execution time in milliseconds

RotationsNumber="2"= Total number of rotational processes: 2D only

1D

The placement data set by the "PlacementPriority1D" option is placed in

.

If "Priority for number of processes" (lrProcesses) and "Priority for length of remnants" (lrRemnants) give different calculation results, the other calculation result is described in the following tag.

<ProcessNumberPriorityPanelSawList>

<RemnantsLengthPriorityPanelSawList>

-->

<PanelSaw Count="1" SourceIndex="0" PartitionID="0" PartitionIndex="0" PartitionCount="0" LayoutNumber="0" RotationsNumber="2">

<!--

<PanelSaw>Listing for one layout picture

1D

Count=Number of copies of the same figure

SourceIndex=

2D

Count=Number of copies of the same figure

SourceIndex=

PartitionID=If PanelSaw is a split, the source of the split is numbered from "1". "0" is not split.

PartitionIndex=Number assigned from "0" within the same "PartitionID

PartitionCount=Indicates the number of copies divided within the same "PartitionID".

LayoutNumber="0"=Unique drawing number in

.

RotationsNumber="2" =Number of rotational processes in this figure.

-->

<BoardNode Category="cgVcut" SizeX="950" SizeY="450" OriginY="0" OriginX="0">

<BoardNode Category="cgHCut" SizeX="500" SizeY="450" OriginY="0" OriginX="0">

<BoardNode Category="cgPartsSide" SizeX="500" SizeY="400" OriginY="0" OriginX="0" ColCount="1" RowCount="2" PartsIndex="1"/>

<BoardNode Category="cgSpace" SizeX="500" SizeY="50" OriginY="400" OriginX="0"/>

</BoardNode>

<BoardNode Category="cgHCut" SizeX="450" SizeY="450" OriginY="0" OriginX="500">

<BoardNode Category="cgVcut" SizeX="450" SizeY="300" OriginY="0" OriginX="500">

<BoardNode Category="cgPartsSide" SizeX="400" SizeY="300" OriginY="0" OriginX="500" ColCount="1" RowCount="1" PartsIndex="0"/>

<BoardNode Category="cgSpace" SizeX="50" SizeY="300" OriginY="0" OriginX="900"/>

</BoardNode>

<BoardNode Category="cgSpace" SizeX="450" SizeY="150" OriginY="300" OriginX="500"/>

</BoardNode>

</BoardNode>

<!--

1D <LineData>

ex.

<PanelSaw Count="1" SourceIndex="0">

<LineData Count="1">0</LineData>

<LineData Count="1">1</LineData>

<LineData Count="1">2</LineData>

</PanelSaw>

In the example, 0, 1, and 2 are the parts panel numbers. Count="1" is the number of parts in the

for that part.

2D <BoardNode>

Cutting a board once results in two pieces. Cutting one of the boards will result in two more boards.

In other words, the data structure is a two-branch tree structure. The bottom of the hierarchy is the parts panel or remnants data.

If you draw the data as it is, it will be as shown in the application.

The

tag in the PartsIndex provides information such as size, comments, and so on.

Category="cgVcut" This board is cut vertically

Category="cgHcut" This board is cut horizontally

Category="cgPartsSide" Parts placed without orientation

Category="cgPartsLength" Parts placed with orientation The part

Category="cgSpace" The remaining parts

OriginY="0" OriginX="0" The coordinates of this part with the upper left corner of PanelSaw as (0,0)

SizeX="950" SizeY="450" The size of this part normalized to an integer

ColCount="1" RowCount="1 "Number of columns and rows for multiple rows of the same part

PartsIndex=part number

RotationsNumber=intermediate data for counting the number of rotations processes

-->

</PanelSaw>

</PanelSawList>

<PrintSetUp Unit="mm" FixedRatio="true" PrintPartsList="true" PrintMemo="false" ViewCost="true" UnitCost="true" OneDNotation="2">

<Columns Number="2" Between="13"/>

<Margin Top="20" Bottom="20" Left="10" Right="10"/>

<Header Left="" Center="" Right=""/>

<Footer Left="" Center="&p/&P" Right=""/>

</PrintSetUp>

<!--

Page setup for printing

-->

</RectPacker>