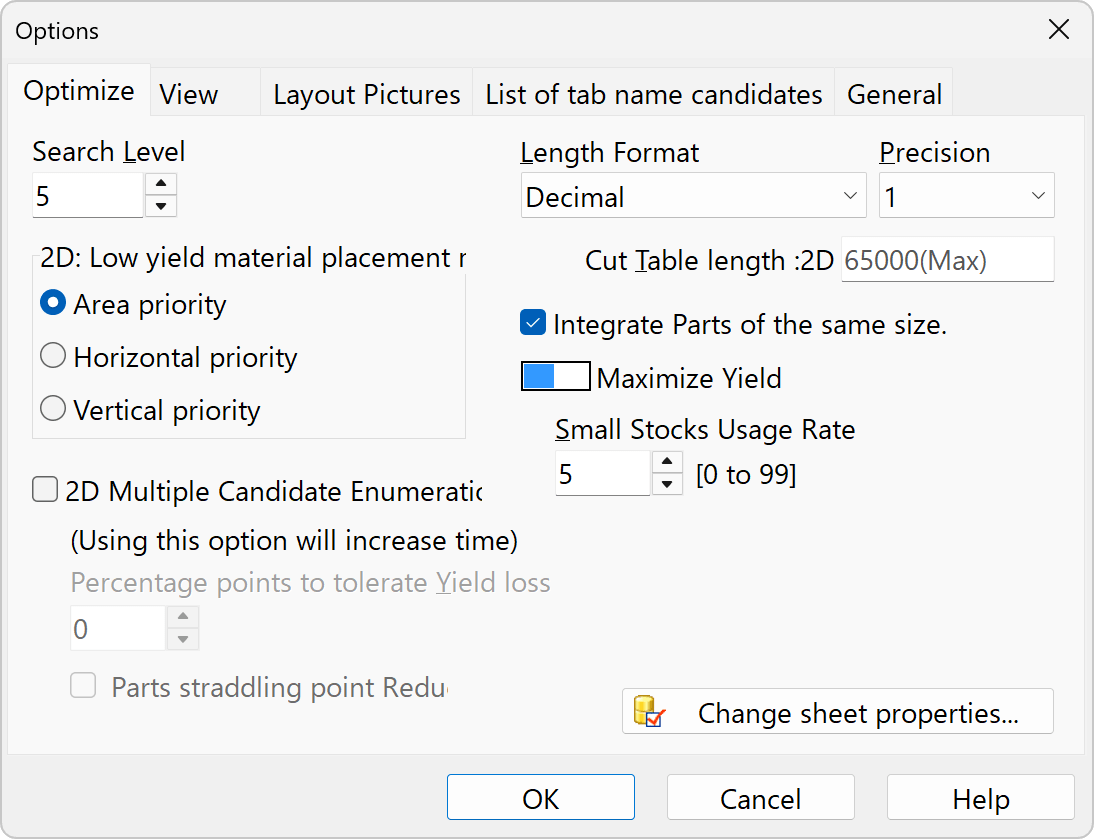

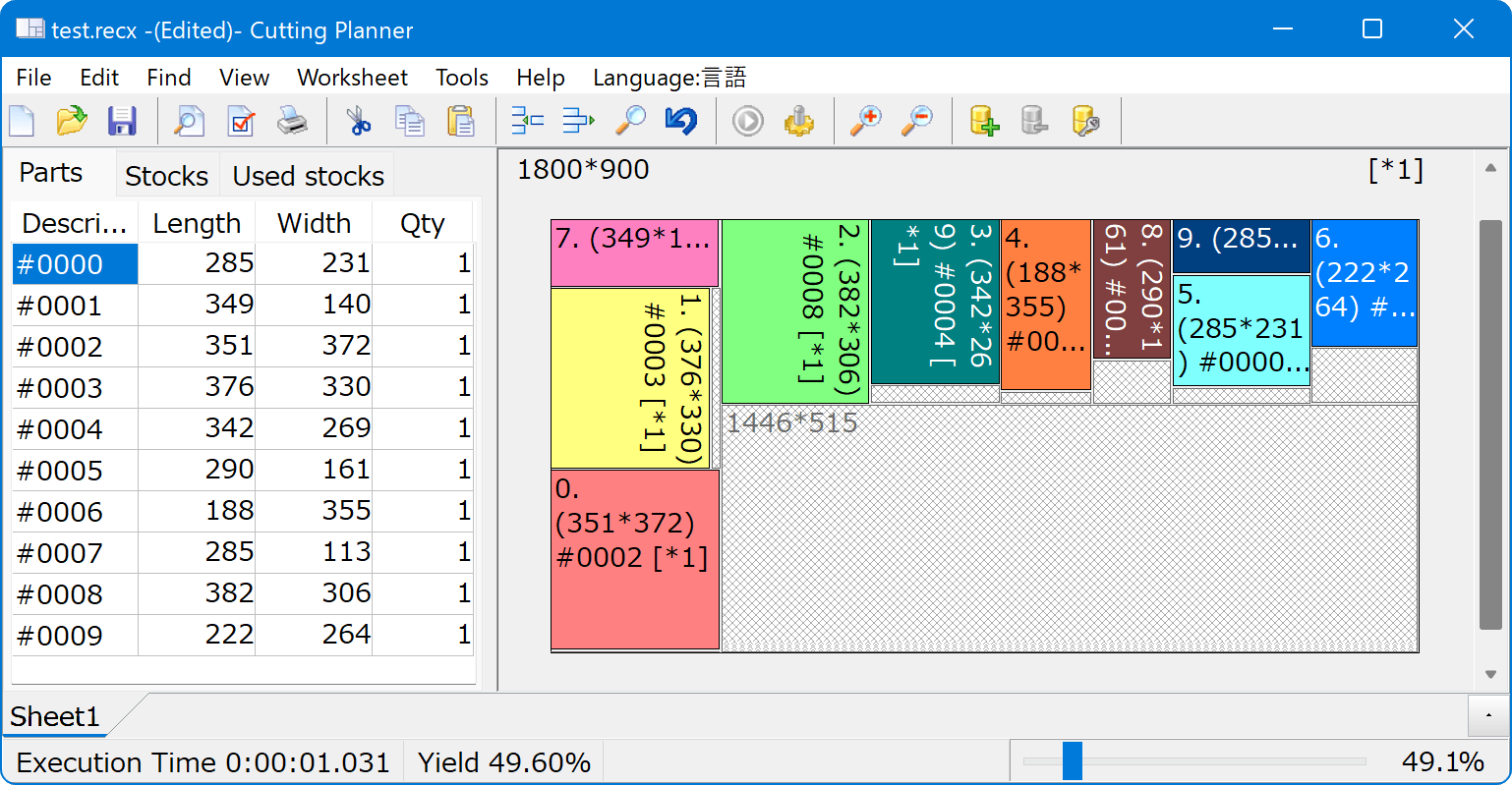

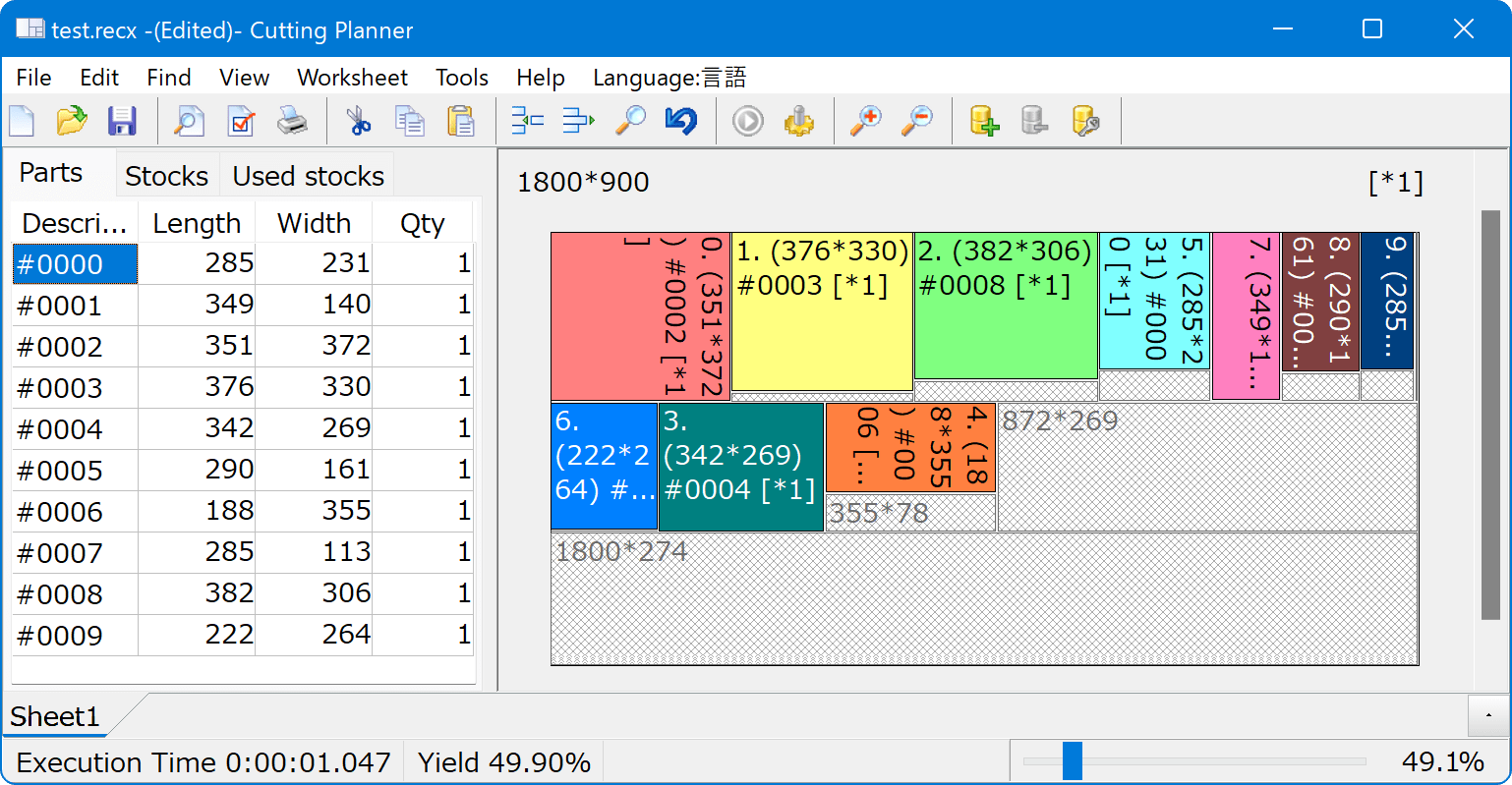

Options - Optimize

Search Level

Sets the balance between computation time and optimization. The longer and more numerous the search, the better solution may be found. Since most problems are not permanently terminated, this setting will terminate the search as converged if no better solution is updated in the specified number of seconds than the current latest solution during the search.

Since the search is terminated by time, different results may be obtained for the same problem depending on the performance of the PC. In other words, the slower the CPU, the longer the setting should be. Since the program supports multi-core processors, the PC with more cores will have an advantage. Also, the same problem and the same PC may produce different results depending on the timing because of the multi-core processor support. Problems with fewer possible combinations may finish earlier than this time." 0" gives the fastest results.

Methods of leaving Remnants

Area priority

Horizontal priority

Vertical priority

Length Format and Precision

- Decimal

e.g. 123.4 mm; 12.3"

Please assume the unit of numerical value freely, such as millimeter or inch. - Feet and decimal inches

例:10' 3.5" - Fractional inches

e.g. 12-31/32" - Feet and fractional inches

e.g. 12' 3-63/64"

The denominator of fraction inch corresponds to 2, 4, 8, 16, 32, 64,128within the setting accuracy.

Unit symbols in feet · inch correspond to the following. Unit sign infeet[ft], ['], ['] Inch unit symbol [in], ["], ["]

In case of inch input, the symbol on the right end can be omitted.

Precision

Sets the minimum unit. For decimal points, set the number of digits forthedecimal portion. The range of valid values (see below) will change."Lengthsettings such as "Saw kerf size" and "Cut table length" also followthissetting. For parts and stock panel data input, if the data is outside thevalidvalues, the text color of the data turns red and the data is ignored intheplacement calculations. It is automatically reset to a sufficient accuracy required at the time of calculation.

Changing the "Length format" and "Precision" willnotconvert data that has already been entered.

Small stocks usage rate

The number is from 0 to 100. The larger the number, the more priority isgivento the stocks panel with the smaller area. The smaller size is assumedforreasons such as lower unit cost and easier handling. The setting can bechangedwhile checking the actual placement calculation results.

"First usage stocks" specifies the stocks panel to be consumedfirst,regardless of this setting. This is used when you want to dispose oftheremaining material inventory.

Cut table length

Specify the maximum size the cutting machine can cut.

For example, if the board is 4200*600 but the panel saw can only cut upto1850. If nothing is entered, there is no limit (see Valid Value Ranges,OtherMaximum Lengths below). Horizontally long materials will be dividedanddisplayed based on this value.

Enter a value in the format based on the "Length Format" and"Precision"settings.

Saw kerf size

This setting item has been moved to "Sheet Properties".

Integrare Parts of the same size

If checked, parts panels of the same size are merged together in theplacementcalculation.

Maximize Yield / Minimize Cost

If [Maximize Yield: Default] is selected, it does not affect the placement calculation.

[If you select “Minimize Cost of Source Plate”, you need to set the unit price for all of the list of source plates.

In most cases, “Maximize Yield” is sufficient, such as when there is only one type of base plate, or when there is no significant difference in the unit cost per area.

2D Multiple candidate enumeration

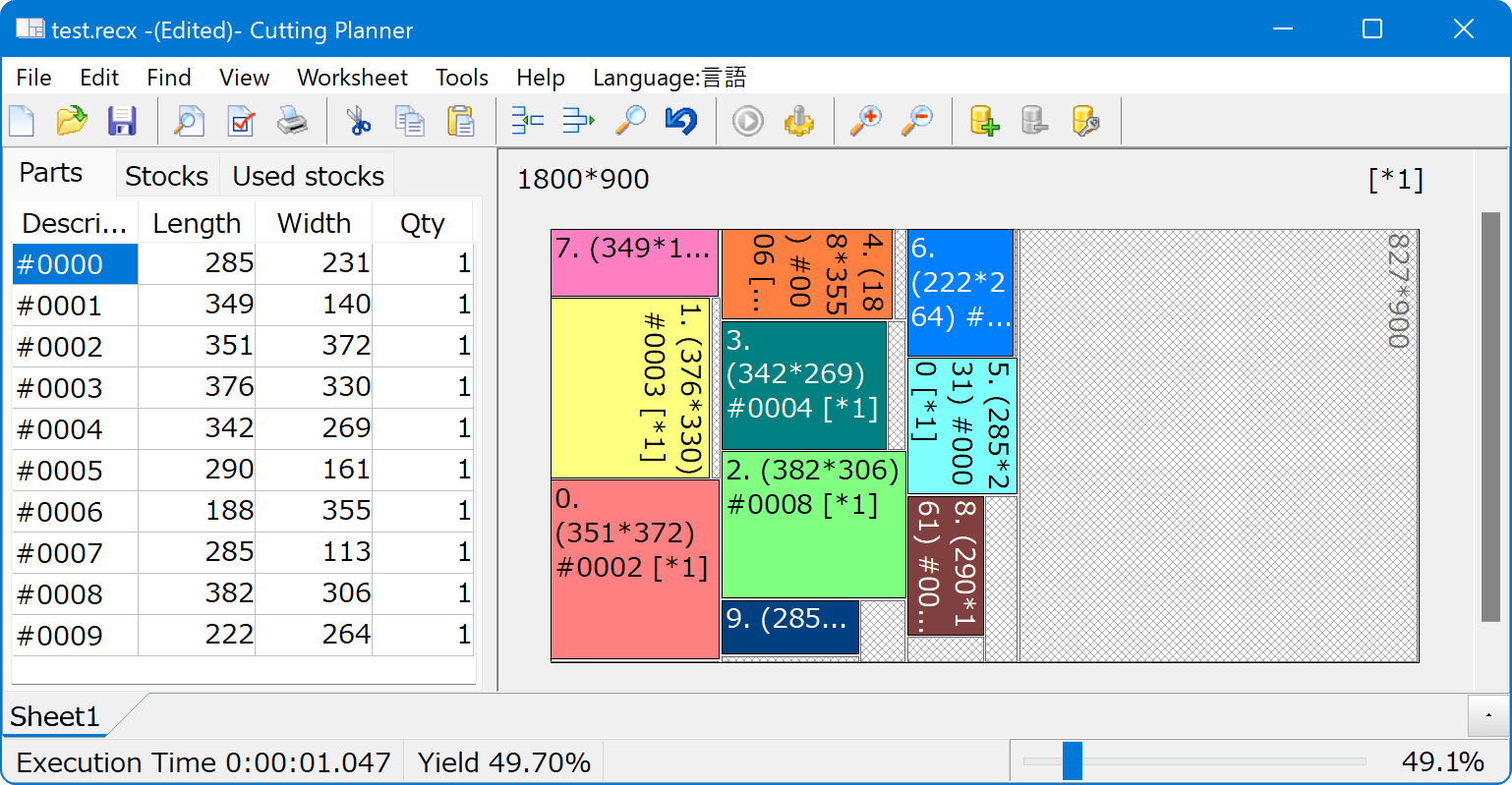

Just as 1D optimization allows you to choose between priority for the number of processes (number of figures) and priority for the length of remaining material, 2D also enumerates multiple candidates for placement.

Refer to the link

Sheet Properties

Sets whether parts panels can be rotated or not, etc. See the link.